Laser Cutting

Up to 6000 X 2500

Up to 20 MM thickness

Advance Laser Cutting Services

Our laser cutting services, among the most sought-after in the market, are widely utilized by a diverse customer base across various industries, including oil & gas, automotive, architecture, power, heavy engineering, chemical, pharmaceutical, shipbuilding, aerospace and defence, mining, and earthmoving equipment. We offer laser cutting with materials to streamline the manufacturing process, enabling our customers to efficiently complete their projects on time and meet their target deadlines.

Why Laser Cutting

The Laser cutting method involved the use of high powered guided laser Beam to cut your base material precise. With high accuracy. The Cutting Accuracy is higher for Small shape and Small article and and small holes. The Laser technology is environmentally friendly because use less energy and gives high cut quality and Parts.

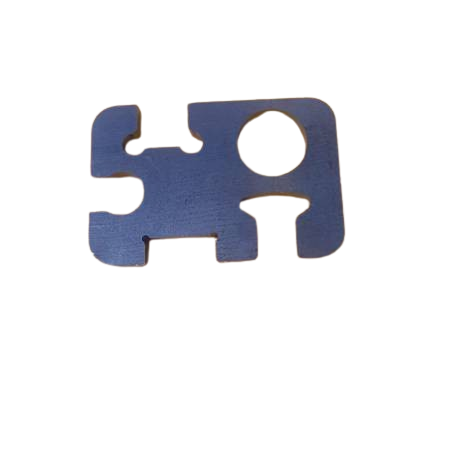

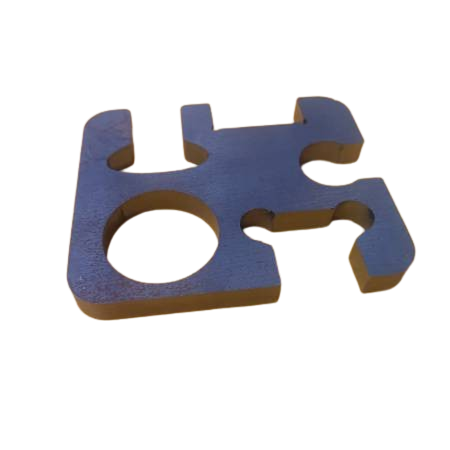

Laser Images

Benefits of laser cutting

This cutting method involves the use of a high-powered, computer-guided laser beam to precision cut your base materials. With no wear on a laser beam, cutting is consistent and incredibly accurate. There is a lower risk of contamination due to the absence of a cutting edge and with minimal Heat Affected Zones (HAZ) the structural integrity of the metal remains intact.

The accuracy of Aarvi Iron Pvt. Ltd.’s state of the art laser cutting machinery allows for the cutting of highly intricate shapes and smaller apertures, with excellent tolerances. With an ability to laser etch hole positions and bend lines over multiple facilities up to 20kW, Aarvi Iron Pvt. Ltd. can confidently deliver a rapid turnaround for even the largest of projects.

- Quick turnaround time due to multiple facilities up to 20kW

- High cut quality and finish

- Clean cut edge finish with virtually no taper

- Highly accurate with very good tolerances

- Ability to cut intricate shapes and smaller apertures

- Ability to laser etch hole positions and bend lines, saving fabrication time

- Fibre laser technology is environmentally friendly because it uses less energy

Delivery times

Our dedicated fleet of vehicles can give you a premium delivery service throughout the Ahmedabad and Gujarat. We are renowned for our flexibility so please speak to us to discuss all the available options.

Material we cut

- M.S Cutting up to 20 MM

- Stainless steel Cutting ( ss202, ss304, ss316, ss321, ss310, ss409, ss410, ss420 ) - up to 16 MM

- Aluminum Cutting - up to 12 MM

- Duplex

- Hardox 4series & 5 series

Benefits

- Multiple facilities up to 20kW

- Quick turnaround time due to facilities up to 20kW

- High cut quality and finish

- Clean cut edge finish with virtually no taper

- Highly accurate with very good tolerances

- Ability to cut intricate shapes

- Ability to cut smaller apertures

- Ability to laser etch hole positions and bend lines, saving fabrication time

- Fibre laser technology is environmentally friendly because it uses less energy